Authors

IOT-OPEN.EU Reloaded Consortium partners proudly present the 2nd edition of the Introduction to the IoT book. The complete list of contributors is juxtaposed below.

ITT Group

- Raivo Sell, Ph. D., ING-PAED IGIP

- Rim Puks, Eng.

- Mallor Kingsepp, Eng.

Riga Technical University

- Agris Nikitenko, Ph. D., Eng.

- Karlis Berkolds, M. sc., Eng.

- Anete Vagale, M. sc., Eng.

- Rudolfs Rumba, M. sc., Eng.

Silesian University of Technology

- Piotr Czekalski, Ph. D., Eng.

- Krzysztof Tokarz, Ph. D., Eng.

- Oleg Antemijczuk, M. sc., Eng.

- Jarosław Paduch, M. sc., Eng.

- Godlove Suila Kuaban, M. sc., Eng.

Tallinn University of Technology

- Raivo Sell, Ph. D., ING-PAED IGIP

- Karl Läll, B. sc., Eng.

SIA RobotNest

- Karlis Berkolds, M. sc., Eng.

IT Silesia

- Łukasz Lipka, M. sc., Eng.

University of Messina

- Salvatore Distefano

- Rustem Dautov

- Riccardo Di Pietro

- Antonino Longo Minnolo

ITMO University

- Aleksandr Kapitonov, Ph. D., Assoc. Prof.

- Dmitrii Dobriborsci, M. sc., Eng.

- Igor Pantiukhin, M. sc., Eng.

- Valerii Chernov, Eng.

Graphic Design and Images

- Blanka Czekalska, M. sc., Eng., Arch.

- Piotr Czekalski, Ph. D., Eng.

Reviewers (1st edition)

- Fabio Bonsignorio, Ph. D., Eng.– Professor at Scuola Superiore Sant'Anna, Institute of Biorobotics

- Artur Pollak, M. sc., Eng. – CEO at APAGroup

- Ivars Parkovs, M. sc., Eng. – R&D Senior Engineer at “SAF Tehnika” Ltd.

- Janis Lacaunieks, M. sc., Eng. – R&D Engineer at “SAF Tehnika” Ltd.

Versions

This page keeps track of the content reviews and versions done as a continuous maintenance process

| Version | Update Date | Content updates summary | Other comments | |

|---|---|---|---|---|

| 1 | v 0.1 | 01.05.2023 | Preliminary version | |

| 2 | v 0.2 | 02.05.2023 | Authors, Preface and Versions | Authors to be updated with consortium partners |

| 3 | v 0.25 | 08.05.2023 | Authors, Preface, Project Information | Authors to be updated with consortium partners |

| 4 | v 0.26 | 18.06.2023 | Introduction chapter revised | |

| 5 | v 0.27 | 28.06.2023 | Updated contents of the Mobility (Fog, edge), enabling technologies, IoT definition | |

| 6 | v 0.28 | 28.06.2023 | Introduction to the Embedded Programming updated: exposed edge class devices and modified Scripting section for Fog devices. Introduction to the Programming Frameworks updatd to expose Edge class and refer to fog. | |

| 7 | v 0.29 | 28.06.2023 | Updated Analogue section in embeddedcommunicationprotocols | |

| 8 | v.0.3 | 19.08.2023 | Reviewed and revised Actuators | |

| 9 | v.0.31 | 20.08.2023 | Updated hardware specific extensions for C++ programming | |

| 10 | v.0.32 | 21.08.2023 | Implemented PWM |

Preface

This book and its offshoots were prepared to provide comprehensive information about the Internet of Things on the engineering level.

Its goal is to introduce IoT to bachelor students, master students, technology enthusiasts and engineers willing to extend their current knowledge with the latest hardware and software achievements in the scope of the Internet of Things.

This book is also designated for teachers and educators willing to prepare a course on IoT.

We (Authors) assume that persons willing to study this content possess some general knowledge about IT technology, i.e. understand what an embedded system is, know the general idea of programming (in C/C++) and are aware of wired and wireless networking as it exists nowadays.

This book constitutes a comprehensive manual for IoT technology; however, it is not a complete encyclopedia nor exhausts the market. The reason for it is pretty simple – IoT is so rapidly changing technology that new devices, ideas and implementations appear daily. Once you read this book, you can quickly move over the IoT environment and market, easily chasing ideas and implementing your IoT infrastructure.

We also believe this book will help adults that took their technical education some time ago to update their knowledge.

We hope this book will let you find brilliant ideas in your professional life, see a new hobby, or even start an innovative business.

Playing with real or virtual hardware and software is always fun, so keep going!

Project Information

ThisBook was implemented under the Erasmus+ KA2 projects:

- Strategic Partnerships in the Field of Education, Training, and Youth – Higher Education, 2016, IOT-OPEN.EU – Innovative Open Education on IoT: Improving Higher Education for European Digital Global Competitiveness, project number: 2016-1-PL01-KA203-026471,

- Cooperation Partnerships in higher education, 2022, IOT-OPEN.EU Reloaded: Education-based strengthening of the European universities, companies and labour force in the global IoT market, project number: 2022-1-PL01-KA220-HED-000085090.

Erasmus+ Disclaimer

This project has been funded with support from the European Commission.

This publication reflects the views only of the author, and the Commission cannot be held responsible for any use which may be made of the information contained therein.

Copyright Notice

This content was created by the IOT-OPEN.EU Consortium: 2016–2019 and IOT-OPEN.EU Reloaded Consortium 2022-2025.

The content is Copyrighted and distributed under CC BY-NC Creative Commons Licence, free for Non-Commercial use.

In case of commercial use, please contact IOT-OPEN.EU Reloaded Consortium representative.

Introduction

Here comes the Internet of Things. The name that recently makes red-hot people in business, researchers, developers, geeks and … students. The name that non-technology related people consider a kind of magic and even a danger to their privacy. The EU set the name as one of the emerging technologies and estimated the worldwide market will hit well over 500 billion US dollars in 2022, while the number of IoT devices in 2030 is expected to be over 3.2 billion.

What is IoT (Internet of Things), then? Surprisingly, the answer is not straightforward.

Color coding

To simplify the selection of different topics, a simple colour coding was introduced, indicating the skills required to cover particular topics. Colour codes are organized in the form of colour bars enclosing chapter titles.

Explanation:

This chapter is for beginners (including amateurs) or higher

This chapter is for bachelor students of higher

This chapter is for master students of higher

Definition of IoT

Let us roll back to the 1970s first. In 1973 the first RFID device was patented. This device was the key enabling technology even if it does not look nor remind modern IoT devices. The low power (actually here passive) solution with a remote antenna large enough to collect energy from the electromagnetic field and power the device brought an idea of uniquely identifiable items. That somehow mimics well-known EAN barcodes and the evolution used nowadays, like QR codes, but every single thing has a different identity here. In contrast, EAN barcodes present a class of products, not an individual one. The possibility to identify a unique identity remotely became fundamental to the IoT as it's known today. RFID is not the only technology standing behind IoT. In the 1990s, the rapid expansion of wireless networks, including broadband solutions like cellular-based data transfers with their consequent generations, enabled connecting devices in various, even distant geographical locations. Parallelly an exponential increase in the number of devices connected to the global Internet network was observed, including the smartphone revolution that started around mid the first decade of the XXI century. On the hardware level, microchips and processors became physically smaller and more energy efficient yet offering growing computing capabilities and memory size increase, along with significant price drops. All those facts drove the appearance of small, network-oriented, cheap and energy-efficient electronic devices. In recent years, the development of efficient AI technologies even boosted IoT applications.

What is IoT?

The phrase “Internet of Things” was used for the first time in 1999 by Kevin Ashton – an expert on digital innovation. Formally IoT was introduced by the International Telecommunication Union (ITU) in the ITU Internet report in 2005 [1]. The understanding and definitions of IoT changed over the years, but now all agree that this cannot be seen as a technology issue only. According to IEEE “Special Report: Internet of Things” [2] released in 2014, IoT is:

| IEEE Definition of IoT |

|---|

| A network of items – each embedded with sensors – connected to the Internet. |

It relates to the physical aspects of IoT only. The Internet of Things also addresses other aspects that cover many areas [3]:

- enabling technologies,

- software,

- applications and services,

- business models,

- social impact,

- security and privacy aspects.

IEEE, as one of the most prominent standardisation organisations, also works on standards related to the IoT. The primary document is IEEE P2413™ [4]. It covers the technological architecture of IoT as three-layered: sensing at the bottom, networking and data communication in the middle, and applications on the top. It is essential to understand that IoT systems are not only small, local-range systems. ITU-T has defined IoT as:

| ITU-T Definition of IoT |

|---|

| A global infrastructure for the information society, enabling advanced services by interconnecting (physical and virtual) things based on existing and evolving interoperable information and communication technologies. |

In the book [5] by European Commission, we can read a similar description of what IoT is: “The IoT is the network of physical objects that contain embedded technology to communicate and sense or interact with their internal states or the external environment.” IoT impacts many areas of human activity: manufacturing, transportation, logistics, healthcare, home automation, media, energy saving, environment protection and many more. In this course, we will consider the technical aspects mainly.

"Thing"

In the IoT world, the “thing” is always equipped with some electronic element that can be as simple as the RFID tag, an active sensor sending data to the global network, or an autonomous device that can react to environmental changes. In CERP-IoT book “Visions and Challenges” [6] in the context of “Internet of Things” a “thing” could be defined as:

| CERP-IoT Definition of “Thing” |

|---|

| A real/physical or digital/virtual entity that exists and moves in space and time and can be identified. Assigned identification numbers, names and location addresses commonly identify things. |

It is quite easy to find other terms used in the literature like “smart object”, “device”, or “nodes” [7].

Passive Thing

One can imagine that almost everything in our surroundings is tagged with an RFID element. They do not need a power supply; they respond with a short message, usually containing the identification number. Modern RFID can achieve 6 to 7 meters of the range. Using the active RFID reader, we can quickly locate lost keys and know if we still have the butter in the fridge and in which wardrobe there is our favourite t-shirt.

Active Thing

If the “thing” includes the sensor, it can send interesting data about current conditions. We can sense environmental parameters like temperature, humidity, air pollution, pressure, localisation data, water level, light, noise, and movement. Using different methods and protocols, this data can be sent to the central collector that connects to the Internet and the database or cloud. There the data can be processed, and Artificial Intelligence algorithms can be used to decide actions that could be taken in different situations. Active things can also receive control signals from the central controller to control the environment: turn on/off the heating or light, water flowers, and turn on the washing machine when there is enough sunlight to generate the required electricity or charge your electric car.

Autonomous Thing

This thing does not even require the controller to realise the proper decision. An autonomous vacuum cleaner can clean our house when it detects that we aren't home and the floor needs cleaning. The fridge can order our favourite beverage once the last bottle is almost empty.

Sensor Network

Sensor Networks are a subset of the IoT devices used as a collaborative solution to grab data and send it for further processing. Opposite to the general IoT devices, Sensor Network devices do not have any actuators that can apply an action to the external world. The data flow is unidirectional, then.

IoT vs Embedded Systems

IoT systems and embedded systems share almost the same domain. They frequently use the same microcontrollers, sensors and actuators, development software and even programming models. What differs between IoT and embedded systems is that IoT, on its principles, uses communication to send and receive data outside of its instance, while embedded systems do not have to. Embedded systems do not have to be network-enabled, and they do not have a unique identity frequently, while IoT devices do. Moreover, IoT systems are complex and multilayered, often introducing cloud-based parts, while embedded systems are stand-alone devices. Shortly we can say that an IoT device is network enabled embedded system.

Enabling Technologies

In this chapter, there is an approach to describe modern technologies that appeared in the last few years, enabling the idea of IoT to be widely implementable. In the [8] one can read that “The confluence of efficient wireless protocols, improved sensors, cheaper processors and a wave of startups and established companies made the concept of the IoT mainstream”. Similar analysis has been done in [9] where authors write that “the latest developments in RFID, smart sensors, communication technologies and Internet protocols enable the IoT”. RFID and smart sensors need the microprocessor system to read, convert the data into digital format, and send it to the Internet using the communication protocol. This process can be done by small- and medium-scale computer (embedded) systems. These are essential elements of technologies used in IoT systems.

Edge class devices

In recent years one can observe rapid growth in the field of microprocessors. It includes not only the powerful desktop processors but also microcontrollers – elements that are used in small-scale embedded systems. We can also notice the popularity of microprocessor systems that can be easily integrated with other factors, like sensors, and actuators, connected to the network. Essential is also the availability of programming tools and environments supported by different companies and communities. An excellent example of such a system is Arduino. Those devices are low-power, constrained devices, usually battery-powered and, in most cases, communicating wirelessly.

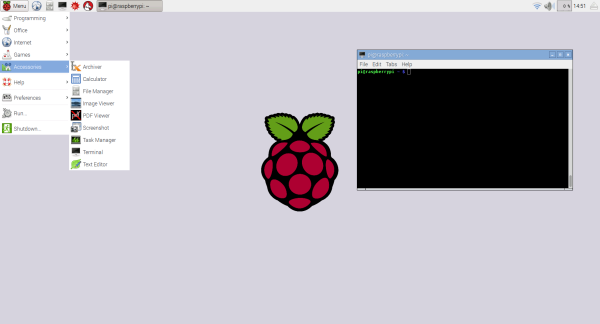

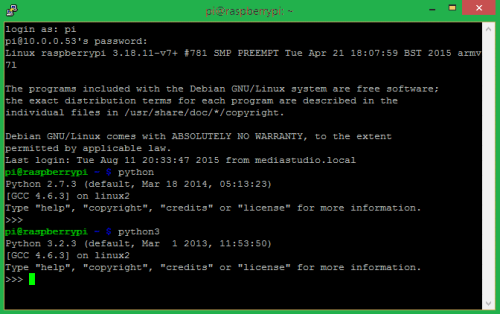

Fog class devices

The same growth can be observed in the advanced constructions comparable to low-end computers. They have more powerful processors, memory and networking connectivity built-in than small-scale computer systems. They can work under the control of multitasking operating systems like Linux and Windows and embedded or real-time operating systems like FreeRTOS. Having many libraries, they can successfully work as hubs for local storage, local controllers and gateways to the Internet. Raspberry Pi and the nVidia Jetson series are examples of such systems. This category of devices frequently contains hardware accelerated (such as GPU) AI-capable solutions, i.e. nVidia Jetson Nano or Xavier series. Those devices can be battery or mains powered. Often, they are green energy powered: i.e. with a larger backup battery and energy harvesting solution (such as solar panel).

Access to the Internet

Nowadays, the Internet is (almost) everywhere. There are lots of wireless networks available in private and public places. The price of cellular access (3G/4G/5G) is low, offering a suitable data transfer performance. Connecting the “thing” to the Internet has never been so easy.

IP Addressing Evolution

The primary paradigm of IoT is that every unit can be individually addressed. With the addressing scheme used in IPv4, it wouldn't be possible. IPv4 address space delivers “only” 4 294 967 296 of unique addresses (2^32). If you think it's a considerable number, imagine that every person in the world has one IP-connected device – IPv4 covers about half of the human population. The answer is IPv6 with a 128-bit addressing scheme that gives 3.4 × 10^38 addresses. It will be enough even if everyone has a billion devices connected to the Internet.

Data Storage and Processing

IoT devices generate the data to be stored and processed somewhere. If there is a couple of sensors, the amount of data is not very big, but if there are thousands of sensors generating data hundreds of times every second. The cloud can handle it – the massive place for the data with tools and applications ready to help with data processing. Some big, global clouds are available for rent, offering not only storage but also Business Intelligence tools, Artificial Intelligence analytic algorithms. There are also smaller private clouds created to cover the needs of one company only. Many universities have their own High-Performance Computing Centre.

Mobile Devices

Many people want to be connected to the global network everywhere, anytime, having their “digital twin” with them. It is possible now with small, powerful mobile devices like smartphones. Smartphones are also elements of the IoT world, being together sensors, user interfaces, data collectors, wireless gateways to the Internet, and everything with mobility features.

The technologies we mentioned here are the most recognisable. Still, there are many others, more minor, described only in the technical language in some standard description document, hidden under the colourful displays between large data centres, making our IoT world operable. In this book, we will describe some of them.

A special note on Fog class and Edge class devices

Technology development instantly shifts devices between categories. A border between Fog and Edge class devices is conventional; many can share both worlds. It depends on their purpose, application and performance configuration; thus, i.e. Raspberry Pi can be an end-node (Edge) class device and a Fog class, working as a data aggregator and analytical device.

Mobility – New Paradigm for IoT Systems

IoT has already been defined as a network of physical things or devices that might include sensors or simple data processing units, complex actuators, and significant hybrid computing power. Today IoT systems have transitioned from being perceived as sensor networks to smart-networked systems capable of solving complex tasks in mass production, public safety, logistics, medicine and other domains, requiring a broader understanding and acceptance of current technological advancements, including advanced data processing that includes AI.

Since the very beginning of sensor networks, one of the main challenges has been data transport and data processing, where significant efforts have been put by the ICT community towards service-based system architectures. However, The current trend already provides considerable computing power even in small mobile devices. Therefore, the concepts of future IoT already shifted towards smarter and more accessible IoT devices, and data processing has become possible closer to the Fog and Edge.

Cloud Computing

Cloud-based computing is a relatively well-known and adequately employed paradigm where IoT devices can interact with remotely shared resources such as data storage, data processing, data mining and other services are unavailable to them locally because of the constrained hardware resources (CPU, ROM, RAM) or energy consumption limits. Although the cloud computing paradigm can handle vast amounts of data from IoT clusters, the transfer of extensive data to and from cloud computers presents a challenge due to limited bandwidth[10]. Consequently, there is a need to process data near data sources, employing the increasing number of smart devices with enormous processing power and a rising number of service providers available for IoT systems.

Fog Computing

Fog computing addressed the bottlenecks of cloud computing regarding data transport while providing the needed services to IoT systems.

It is a new trend in computing that aims to process the data near the data source. Fog computing pushes applications, services, data, computing power, and decision-making away from the centralised nodes to the logical extremes of a network. Fog computing significantly decreases the data volume that must be moved between end devices and the cloud.

Fog computing enables data analytics and knowledge generation at the data source. Furthermore, the dense geographic distribution of fog helps to attain a better-localised accuracy for many applications than the cloud processing of the data [11].

The recent development of energy-efficient hardware with AI acceleration enters the fog class of the devices, putting Fog Computing in the middle of the interest of IoT application development and extending new horizons to them. Fog Computing is more energy efficient than raw data transfer to the cloud and back, and in the current scale of the IoT devices, the application is meant for the future of the planet Earth. Fog Computing usually also brings a positive impact on IoT security, i.e. sending to the cloud preprocessed and depersonalised data and providing distributed computing capabilities that are more attack resistant.

Edge Computing

Recent development in hardware, power efficiency and a better understanding of the IoT data nature, including such aspects as, i.e. privacy and security, led to solutions where data is being processed and preprocessed right to their source in the Edge class devices. Edge data processing on end-node IoT devices is crucial in systems where privacy is essential and sensitive data is not to be sent over the network (i.e. biometric data in a raw form). Moreover, distributed data processing can be considered more energy efficient in some scenarios where, i.e. extensive, power-consuming processing can be performed during green energy availability.

Cognitive IoT Systems

According to [12], Cognitive IoT, besides a proper combination of hardware, sensors and data transport, comprises cognitive computing, which consists of the following main components:

- understanding – in the case of IoT, it means systems' capability to process a significant amount of structured and unstructured data, extract the meaning of the data – produce a model that binds data to reality;

- reasoning – involves decision-making according to the understood model and acquired data;

- learning – creating new knowledge from the existing, sensed data and elaborated models.

Usually, cognitive IoT systems or C-IoT are expected to add more resilience to the solution. Resilience is a complex term and is differently explained under different contexts; however, there are standard features for all resilient systems. As a part of their resilience, C-IoT should be capable of self-failure detection and self-healing that minimises or gradually degrades the system's overall performance. In this respect, the non-resilient system fails or degrades in a step-wise manner. In case of security issues, that system should be able to change its security keys, encryption algorithms and take other measures to cope with the detected threats. Self-optimisation abilities are often considered part of the C-IoT feature list to provide more robust solutions. Recent development in the Fog and Edge class devices and the efficient software leverage cognitive IoT Systems to a new level.

All three approaches, from cloud to cognitive systems, focus on adding value to IoT devices, system users and related systems on-demand. Since market and technology acceptance of mobile devices is still growing, and the amount of produced data from those devices is growing exponentially, mobility as a phenomenon is one of the main driving forces of the technological advancements of the near future.

Data Management Aspects in IoT

Data management is a critical task in IoT. Due to the high number of devices (things) already available, that is tens of billions, and considering the data traffic generated by each of them through, i.e. sensor networks, infotainment (soft news) or surveillance systems, mobile social network clients, and so on, we are now even beyond the ZettaByte (ZB 2^70, 10^21 bytes) era. This opened up several new challenges in (IoT) data management, giving rise to data sciences and big data technologies. Such challenges have not to be considered as main issues to solve but also as significant opportunities fuelling the digital economy with new directions such as Cloudonomics [13] and IoTonomics, where data can be considered as a utility, a commodity to manage, curate, store, and trade appropriately. Therefore, properly managing data in IoT contexts is not only critical but also of strategic importance for business players as well as for users, evolving into prosumers (producers-consumers).

From a technological perspective, the main aspects of dealing with IoT data management are:

- data source: data generation and production is a relevant part of IoT, involving sensors probing the physical system. In a cyber-physical-social system view, such sensors could be virtual (e.g. software) or even human (e.g. citizens, crowdsensing). The main issues in data production are related to the type and format of data, heterogeneity in measurements and similar issues. Semantics is the key to solving these issues, also through specific standards such as Sensor Web Enablement and Semantic Sensor Network;

- data collection/gathering: once data are generated, these should be gathered and made available for processing. The collection process needs to ensure that the data gathered are defined and accurate so that subsequent decisions based on the findings are valid. Some types of data collection include census (data collection about everything in a group or statistical population), sample survey (collection method that includes only part of the total population), and administrative by-product (data collection is a byproduct of an organisation’s day-to-day operations). Usually, wireless communication technologies such as Zigbee, BlueTooth, LoRa, Wi-Fi and 3G/4G networks are used by IoT smart objects and things to deliver data to collection points;

- filtering: is a specific preprocessing activity, usually performed at data source or data collector (IoT) nodes (e.g. motes, base stations, hotspots, gateways), aiming at cleaning noisy data, filtering noise and not helpful information;

- aggregation/fusion: to reduce bandwidth before sending data to processing nodes, these are further elaborated, compressed, aggregated and fused (sensor/data fusion) to reduce the overall volume of raw data to be transmitted and stored;

- processing: once data are adequately collected, filtered, aggregated, and fused, they can be processed. Processing can be both local and remote and usually includes preprocessing activities to prepare data for real processing. Local processing, when possible, is mainly tasked with a fast, lightweight computation on edges (Edge computing) and in the Fog layer, wherever possible, quickly providing results and local analytics. More complex computations are usually demanded to remote (physical or virtual) servers provided by local nodes (e.g. communication servers, cloudlets) in a Fog computing fashion or by Cloud providers as virtual machines hosted in data centres. This kind of computation can also involve historical data, providing global analytics, but hardly meets time-constrained applications and real-time requirements;

- storage/archive: remote servers are also used for permanently storing and archiving data, making these available for further processing, even to third parties. The database is often used for that, mainly based on distributed, NoSQL key-store technologies to improve reliability and performance;

- delivering/presentation/visualization: processing activity results must then be delivered to requestors and users. These have to be, therefore, adequately organised and formatted, ready for end-users. IoT data visualisation is becoming an integral part of the IoT. Data visualisation provides a way to display this avalanche of collected data in meaningful ways that clearly present insights hidden within this mass amount of information;

- security and privacy: data privacy and security are among the most critical issues in IoT data management. Good results and reliable techniques for secure data transmission, such as TLS and similar, are available. This way, IoT data security issues mainly concern [14] securing IoT devices, since they are usually resource-constrained and therefore do not allow to adopt traditional cryptography scheme to data encryption/decryption. Data privacy and integrity should also be enforced in remote storage servers, anonymising data and allowing owners to properly manage (monitoring, removing) them while ensuring availability. Indeed, security and privacy issues vertically span the whole IoT stack. A promising technique to address IoT security issues, attracting growing interest from both academic and business communities, is blockchain [15].

IoT Application Domains

Application domains of the Internet of Things solutions are vast. Most prominent applications include (among others) [16]:

- building and home automation,

- smart water,

- internet of food,

- smart metering,

- smart city (including logistics, retail, transportation),

- industrial IoT,

- precision agriculture and smart farming,

- security and emergencies,

- healthcare and wellness (including wearables),

- smart environment,

- energy management,

- robotics,

- smart grids.

Smart Homes are one of the first examples that come to mind when discussing Internet of Things domain applications. Smart home benefits include reduced energy wastage, the quality and reliability of devices, system security, reduced cost of basic needs, etc. Some home automation examples are environmental control systems that monitor and control heating, ventilation, air conditioning and sunscreens; electrical charging of vehicles; solar panels for electrical power and hot water; ambient lighting control, smart lighting for aquaria; home cooking and food ordering; access control (doors, garage, gate); smart plant irrigation systems (both indoors and outdoors); baby monitoring; timed pet food dispensers; monitoring perishable goods (for example, in the refrigerator); household items remote monitoring (for instance, of washer cycle status); tracking and proactive maintenance scheduling (such as, i.e. electric car charging); event-triggered task execution. Home security also plays a significant role in smart homes. Examples of applications are automatic door locks, sensors for opening doors and windows, pressure, motion and infrared sensors, security cameras, notifications about security (to the owner or the police) and fitness-related applications.

In Smart City, multiple IoT-based services are applied to different areas of urban settings. The aim of the smart city is the best use of public resources, improvement of the quality of resources provided to people and reduction of operating costs of public administration [17]. A smart city can include many solutions like smart buildings, smart grids for improving energy management, smart tourism, monitoring of the state of the roads and occupation of parking lots, public transportation optimisation, public safety, environment monitoring, automatic street lighting, signalling with smart power devices, control of water levels for hydropower or flood warnings, electricity-generating devices like solar panels and wind turbines, weather monitoring stations. Transportation in smart cities may include aviation, monitoring and forecasting of traffic slowdowns, timetables and current status, navigation and route planning, as well as vehicle diagnostics and maintenance reports, remote maintenance services, traffic accident information collection, fleet management using digital tachographs, smart parking, car/bicycle sharing services [18]. IoT in transportation makes cars interconnected, particularly in the approaching autonomous vehicles era.

Smart Grid is a digital power distribution system. This system gathers information using smart meters, sensors and other devices. After these data are processed, power distribution can be adapted accordingly. Smart grids deliver sustainable, economical and secure electricity supplies efficiently.

In Precision Agriculture and Smart Farming IoT solutions can be used to monitor the moisture of the soil and conditions of the plants, control microclimate conditions and monitor the weather conditions to improve farming [19]. The goal of using IoT in agriculture is maximising the harvest, reducing operational costs, being more efficient, and reducing environmental pollution using low-cost automated solutions. An interaction between the farmer and the systems can be done using a human-machine interface. In the future smart precision farming can be a solution for such challenges as increasing worldwide demand for food, a changing climate, and a limited supply of water and fossil fuels [20].

Internet of Food integrates many of the aforementioned techniques and encompasses different stages of the food delivery chain, including smart farming, food processing, transportation, storage, retail, and consumption. It provides more safety and improved efficiency at each food production and consumption stage, including reduced waste and increased transparency.

Similar to precision agriculture, which is part of IoT in industry, Smart Factories also tend to improve manufacturing by monitoring pollutant gas emissions, locating employees and with many other solutions.

Industrial IoT and smart factories are part of the Industry 4.0 revolution. In this model, modern factories can automate complex manufacturing tasks, thanks to the Machine-To-Machine communication model, which provides more flexibility in the manufacturing process to enable personalised, short-volume product manufacturing easily.

In the healthcare and wellness, IoT applications can monitor and diagnose patients and manage people and medical resources. It allows remote and continuous monitor the vital signs of patients to improve medical care and wellness of patients [21]. An essential part of smart welfare is wearables, including wristbands and smartwatches that monitor the activity level, heart rate and other parameters. Smart healthcare includes remote monitoring, care of patients, self-monitoring, smart pills, smart home care, Real-Time Health Systems (RTHS) and many more. Medical robotics can also be part of the healthcare IoT system that includes medical robots in precision surgery or distance surgery; some robots are used in rehabilitation and hospitals (for example, Panasonic HOSPI [22]) for delivering medication, drinks, etc. to patients.

Wearables used in IoT applications should be highly energy efficient, ultra-low power and small-sized. Wearables are installed with sensors and software for data and information collected about the user. Devices used in daily life like Fitbit [23] are used to track people's health and exercise progress in previously impossible ways, and smartwatches allow to access smartphones using this device on the wrist. But wearables are not limited only to wearing them on the wrist. They can also be glasses equipped with a camera, a sports bundle attached to the shoes or a camera attached to the helmet or as a necklace [24].

Introduction to the IoT Microcontrollers

[ktokarz][✓ ktokarz, 2023-08-23]Describe in general IoT MCUs: CPU, FPU, RAM, Storage (flash), GPIO, Interrupts system, DMA, built-in radio interfaces (if any).

IoT device is, in almost all cases, based on microcontroller. A microcontroller, often called a single-chip computer, is an integrated circuit that incorporates all units required to function as the computer. It includes a central processing unit (CPU), memory for programs, memory for data, inputs, outputs, timers, serial communication ports and other peripherals. Complex microcontrollers, called embedded processors, can include more processor cores, display controllers, advanced internal data transfer mechanisms (like DMA), programmable connections between modules, specialized coprocessors for ciphering and deciphering, compression and decompression, video and audio coding and decoding, and other modules. Microcontrollers are even more complex in the IoT world due to wireless networking capability. A complex microcontroller equipped with an internal radio communication module is also known as a System on Chip (SoC).

The typical microcontroller includes general-purpose units like:

- CPU core,

- Program memory,

- Data memory,

- Timers, Counters,

- Interrupt controller,

- I/O ports,

- Serial synchronous and asynchronous communication ports,

- Analog to Digital converter,

- PWM (Pulse width Modulation unit for Digital to Analog conversion),

- DMA controller,

- Supervisory units (Watchdog, Reset, Brownout).

Embedded Processor or System on Chip can contain also:

- Network interface,

- USB controller,

- Memory interface module,

- Floating point unit (FPU),

- Cryptographic module,

- Other application-specific extensions.

The CPU core is the unit that executes the main program. It controls program flow, executes general-purpose instructions, calculates addresses, and processes integer values. For fast floating point calculations, an FPU coprocessor is built-in. It executes instructions that perform calculations on real numbers and advanced mathematical functions. The program instructions are fetched from program memory, usually implemented as internal or external flash memory. Data is stored in internal data memory implemented as static RAM. If more memory is needed, some microcontrollers have a memory management unit that allows them to connect external DRAM memory. Flash memory is often used as a place for file storage. Timers and counters are units that help to generate pulses of specified length and square signals of specified frequency. They can also measure delays and synchronise the work of other modules like serial ports, converters, and displays. Timers can generate pulse width modulated signals to control the speed of motors and light brightness. Microcontrollers have digital input and output ports to connect other elements of the systems. Connecting external sensors to collect information from the surroundings and output devices to manipulate environmental parameters is possible. Analogue inputs can read the voltage value generated by simple sensors. Serial communication ports are used to connect more complex sensors and displays to communicate with the user or another computer system. An interrupt controller is a unit that automatically executes subroutines responsible for handling tasks specific to the hardware that signalled the situation that needs the processor's attention. The processor doesn’t have to waste execution time by periodically checking if there is a need to take care of the device. It helps to make the code more efficient and reliable. Supervisory units help to recover from some abnormal situations. Watchdog resets the processor in case the software hangs up. Brownout detector constantly monitors the power supply voltage. It stops the processor if the voltage is too low for proper operation to avoid execution errors, flash write errors, and other malfunctions. Supervisory interfaces like JTAG allow writing the programs into flash memory and debugging the code. Direct Memory Access (DMA) module performs memory operations without processor intervention. It is usually used for copying data blocks between memory and other peripheral units. For example, data from the network unit is stored automatically in the buffer, and the CPU is informed while the data transfer is complete.

Details of the internal construction and operation of many internal modules of popular microcontrollers are described in further chapters of this book.

Introduction to Embedded Programming

IoT systems share programming paradigms with embedded systems. Each microcontroller manufacturer has its own set of tools (usually called SDK or Development Framework) that frequently contain an IDE dedicated to the platform. There are some cross-platform solutions and frameworks, however.

Programming languages include:

- C/C++ - undoubtedly the most popular, versatile, yet demanding programming language. With modern supporting tools such as syntax highlights, code samples, code generators (AI-based) and instant syntax checking, C/C++ programming became relatively easy but still requires solid software development foundations. On the other hand, it is probably the only programming language that is natively supported with hardware debugging features. C/C++ bare metal programming allows the developer to control all MCU features on the lowest level and implement energy-efficient, fast and compact solutions.

- Java and Javascript - with low entry-level for developers, usually represented by the variation of NodeJS, limited and applicable to beginners. Within the constraints of the interpreter, it provides rapid prototyping and the fastest market delivery but the lowest flexibility and extensibility beyond what the manufacturer plans. Also, the Java development framework implemented in the microcontroller is compact because of the constrained resources. Usually, it does not keep standards, so the feature of the portability of the code is somewhat limited.

- Python (Micropython) - similarly to Java, offers an easy start but low flexibility and control over the hardware. Acceptable for prototyping.

- Other.

IoT and Embedded Systems Programming Models

IoT device programming can be done on a variety of levels. Below we present the most popular models and briefly discuss their pros and cons.

Bare Metal Programming

The bare metal programming model is where the software developer builds firmware (usually from scratch or based on a stub generated by the SDK) and flashes it to the MCU. The MCU usually does not contain software other than technical ones necessary for starting and updating the device, i.e. a bootloader. The developer must implement all algorithms, communication, interfacing, storage, etc., on a low level. They may use 3rd party libraries to implement it, which speeds up development significantly. There is no operating system running in the background. Eventually, it comes with the firmware as part of it, as included by the developer, i.e. FreeRTOS [25].

Bare metal programming requires a good understanding of the hardware configuration of the IoT device as well as the configuration of the software development toolchain. The MCU manufacturer usually provides SDK and related tools, but there do exist middleware solutions (such as PlatformIO [26]) that significantly simplify installation.

In most cases, source code is written in C or C++ language or their combination (e.g. in the case of the STM). The development process for bare metal programming is present in the following figure 2 and its features are discussed in table 2. In short, it requires developing, compiling and uploading the firmware to the device's flash memory. Programming uses a programmer (physical or Over The Air - OTA, virtual interface). The bare metal model usually provides the capability of hardware development.

The bare metal programming model is considered the only one to enable developers to have absolute control over the hardware on a very low level. On the one hand, it brings opportunities to implement non-standard solutions and optimal code in terms of compactness and efficiency; on the other, it increases time-to-market delivery. Recent advances in development supporting tools (i.e. AI-based code generation), wide availability of the libraries, standardisation of their presence and automated management, such as, e.g. in PlatformIO Library Management [27] significantly lower this time.

| Pros | Cons |

|---|---|

| Absolute control over hardware | Need to implement all from scratch |

| Secure, low vulnerability | Requires good hardware understanding |

| No bottlenecks | Requires advanced programming skills |

| Efficient and compact code | Requires complex development environment |

| Fastest, no overhead of the middleware | Possibility to brick the device during flashing |

| Good community support | Time consuming implementation |

| Highly flexible, enables the developer to prepare non-standard solutions | |

| Provides hardware debugging capabilities | |

| Energy efficient, it gives control over low-level, energy-saving mechanisms (waitstates, sleep modes, radio power, etc.) |

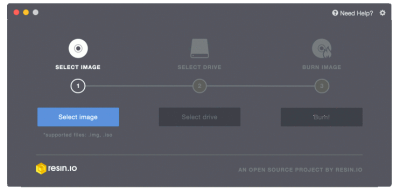

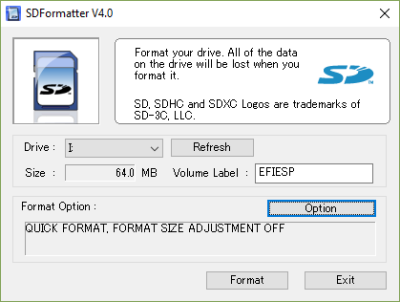

Script Programming with Middleware

Opposite to bare metal programming, script programming does not involve compilation or firmware burning into the flash memory. This programming model uses interpreted languages such as Python (actually Micropython: an edition of Python for microcontrollers dedicated to constrained devices), NodeJS, Javascript, Java, C#, etc. A virtual machine middleware (programming language interpreter) running bare metal (installed as firmware) or as a part of the operating system (if any), and the developer prepares an algorithm as a script, usually in a textual form, later uploaded and executed on the device. The middleware brings an overhead on execution; thus, this solution is intended for not so constrained IoT devices, still acceptable for Edge and quite common for Fog class. It requires much more CPU, RAM and storage than bare metal programming, has limitations from the interpreter implementation and only indirectly accesses hardware. It is not suitable for real-time solutions.

The development process for scripting programming is present in the following figure 3 and its features are discussed in table 3. In short, it requires limited SDK (or none), but debugging is complex, if possible.

This programming model is suitable wherever standard solutions are implemented and where code execution efficiency is not critical, and there is no demand for real-time operations; eventually, the IoT device is unconstrained, providing developers with decent CPU (e.g. modern ARM), RAM and storage. Note those solutions are usually less energy efficient than bare metal programming; still, they offer great flexibility in algorithm implementation, far beyond a predefined list of choices or limited configuration as presented in the following section. On the other hand, it speeds up delivery time to the market because of the ease of implementation, the lack of need to install the complex software development environment and the high level of abstraction.

| Pros | Cons |

|---|---|

| Better suitable for beginners | Not optimal because of the middleware overhead on execution |

| Uses higher abstraction level | Not suitable for real-time operations |

| Uses high-level programming languages | Limited hardware interfacing and features to those exposed by the middleware |

| Usually does not involve complex SDK/development environment | Limited and non-optimal energy efficiency management |

| Flexible enough to implement complex algorithms | Low extendibility |

| Rapid development | Middleware updates used to cause the need to adapt script with algorithm |

| Hardware debugging is tricky or not possible at all |

Configuring Firmware

Several middleware (IoT frameworks) are available for various IoT devices. This development model focuses on reconfiguring the sealed firmware delivered “as is” using some configuration interface or script (or both). Eventually, modifying and recompiling it yourself is possible if it is open source. Still, the process is usually very complex, and understanding all relations and development toolchain sometimes is more complicated than developing a solution from scratch as a bare metal. Proprietary frameworks do not bring this opportunity at all and are delivered “as is” with a predefined set of features. The development is limited to reconfiguring the elements from simply switching them on and off through setting up access and credentials, even up to the GPIO assignment. This usually does not bring capabilities to modify the algorithm, eventually to choose a behaviour from the predefined list proposed by the middleware author. Such a model does not bring debugging capabilities; finally, simple tracking with error codes and log files (if at all). Moreover, in many scenarios, middleware is dependent on some external resources (i.e. authorisation via a cloud or firmware updates delivered with this channel).

The development process for the middleware configuration model is present in the following figure 4 and its features are discussed in table 4.

Configuration range varies among IoT frameworks but commonly requires compatible hardware. Proprietary firmware provides sealed configuration software and encryption; thus, it virtually excludes any non-standard modifications or makes them very complex. IoT hardware used to be compatible with more than one firmware, and proprietary ones can be replaced with another open source, i.e. Tasmota [28]. Configuration in proprietary middleware scenarios can be provided indirectly via a cloud solution that raises serious questions about privacy (i.e. configuring your private WiFi router credentials via a public or 3rd party cloud, not directly to the device).

| Pros | Cons |

|---|---|

| Easy to use even for beginners | Limited number of use scenarios |

| Consistent environment (configuration, use) common look and feel | Problems appearing hard to solve in case of failure |

| No need for SDK, configuration tools use plain text, browsers or apps | Low flexibility - limited support for hardware (only proprietary or limited compatibility in the case of the open source) |

| Manufacturer's support (for proprietary) but usually for a limited time and shorter compared to open source solutions | Doubtful privacy, in particular when a public cloud is in use |

| Usually reliable | Lack of help once Manufacturer's maintenance period is finished |

| During the maintenance period, updates are given by the vendor |

Introduction to the Programming Frameworks

In the beginning, it is essential to distinguish an IoT Framework that is a set of tools, firmware for a variety of devices, sometimes also hardware, delivered as is and providing developers with configuration capabilities on the high abstraction level from the Programming Framework that is related to the low-level programming, here in C/C++, referred to as an SDK. SDK tends to be a narrower definition than a programming framework as the former one contains not only SDK but also tools, development toolchain and code organisation rules.

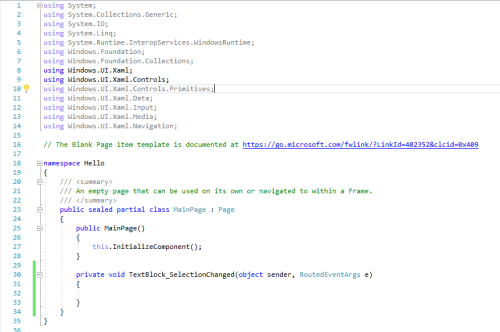

This chapter presents and discusses programming frameworks (SDKs and source code organisation) that define how the IoT code is organised on the low level in the Bare Metal programming model for Edge class devices.

Almost every MCU (microchip/microcontroller) vendor develops its own SDK, providing programmers with a specific programming framework. It is worth nothing to mention that, in many cases, it follows the general programming construction of the source code for C or C++, such as below:

int main() { std::cout << "Hello IoT!"; return 0; }

A common approach is to use a GUI to automate the generation of the source code stub that contains the hardware-specific configuration, i.e. timers, GPIOs, and interrupts, to avoid monotonous and complex tasks and speed up time to market.

Still, as hardware differs, it is particular for each platform, and usually, software development requires a rigorous approach to inject user-specific code only in predefined locations. Otherwise, it may break source code or even delete it when re-generating configuration using SDK tools and automation. Sample main() function for the STM32 MCU is presented below. Developers are intended to fill their code only in predefined areas, such as starting from USER CODE BEGIN Init and finishing before USER CODE END Init; otherwise, the source code will be gone when updating the configuration:

int main(void) { /* USER CODE BEGIN 1 */ /* USER CODE END 1 */ HAL_Init(); /* USER CODE BEGIN Init */ /* USER CODE END Init */ SystemClock_Config(); /* USER CODE BEGIN SysInit */ /* USER CODE END SysInit */ MX_GPIO_Init(); MX_LPUART1_UART_Init(); MX_NVIC_Init(); /* USER CODE BEGIN 2 */ /* USER CODE END 2 */ /* Infinite loop */ /* USER CODE BEGIN WHILE */ while (1) { nUARTBufferLen = sprintf((char*)tUARTBuffer, "Hello World!\n\r"); HAL_UART_Transmit_IT(&hlpuart1, tUARTBuffer, nUARTBufferLen); /* USER CODE END WHILE */ /* USER CODE BEGIN 3 */ } /* USER CODE END 3 */ }

Studying specific platforms is time-consuming, and as each vendor has its own approach, knowledge and source codes are usually not portable between microcontrollers.

Specific frameworks for hardware vendors are (among others):

- Espressif ESP8266:

- ESP8266 RTOS SDK,

- ESP8266 Non-OS SDK,

- Arduino.

- AVR/Atmel:

- AVR Studio (Atmel Studio),

- Arduino.

- Espressif ESP32:

- ESP-IDF,

- Arduino.

- Nordic Semiconductors nRF52:

- Mbed,

- Zephyr RTOS,

- nRF5 SDK,

- Arduino.

- ST Microelectronics STM32 series:

- Mbed,

- CMSIS,

- Zephyr RTOS,

- Registers programming model (RAW),

- STM32Cube (HAL),

- Arduino.

Typical C++ code, as presented above, is a single-pass execution. On the other hand, IoT devices used to work infinitely, handling their duties such as reading sensors, communicating over the network, sending and receiving data, routing messages and so on, thus, requiring setting up an infinite while (1) loop for processing. Many tasks need to be done in parallel, so it is common to include a task scheduling mechanism to run multiple tasks asynchronously. A common is to use the FreeRTOS [29] or its modified versions for the specific hardware platform provided by the hardware vendor, i.e. as in the case of the ESP32 [30] to provide support for multicore MCUs.

Arduino Framework

Observing the list of software frameworks above, one can easily find that many platforms have common frameworks, but the Arduino framework is present for all of them. Arduino framework is a cross-platform approach providing a slightly higher level of abstraction over dedicated software frameworks, and it is the most popular among hobbyists, students, professionals and even researchers at the moment. Arduino Framework is a reasonable balance between uniform code organisation and elements of cross-hardware HAL, still bringing opportunities to access hardware on a low level and get the advantage of the advanced features of modern IoT microcontrollers such as, e.g. power management. Most hardware vendors support this framework natively, and it has become almost an industry standard. Some advanced hardware control may require integration or other native frameworks, anyway. Still, the Arduino framework has real-time capacity. It is powerful and flexible enough to handle most IoT-related tasks, and most of all, it has excellent community support with dozens of software libraries, examples and applications worldwide.

A dummy C/C++ code for the Arduino framework looks as follows:

void setup() { } void loop() { }

The void setup() function is executed only once after the microcontroller reboots. Its purpose is to initialise, instantiate objects, read configuration, check working conditions, and so on: generally, all tasks that are to be executed only once in a work cycle of the IoT device.

The void loop() function is executed in a loop automatically and infinitely once a single pass is finished. Its purpose is to implement repeating tasks such as periodical reading of a sensor and sending the data to the cloud. There is no need to implement a dummy while(1) inside the loop(); moreover, it is usually not advised or even forbidden. It is because, for every execution of the loop() statement, many other tasks, such as handling communication, may be executed once. Making a single pass of the loop() function infinite (i.e. with implementing an infinite while(1) loop, could cause starvation of the other underlying processes the framework handles, such as network communication, embedded protocols handling, etc.).

The book presents code and examples in the Arduino framework context for Edge class devices but also for Fog class devices (scripting). Wherever other framework is used, it will be clearly stated. Note, following introduction to the C and C++ programming and task handling contents, are universal and can be applied to the other frameworks, whether directly or indirectly, with some adaptation on the code level.

Software Development Tools and Platforms

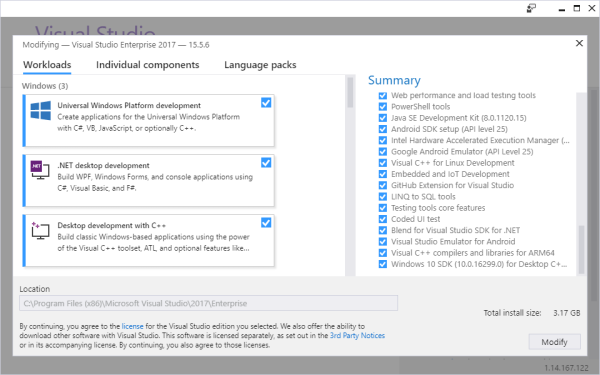

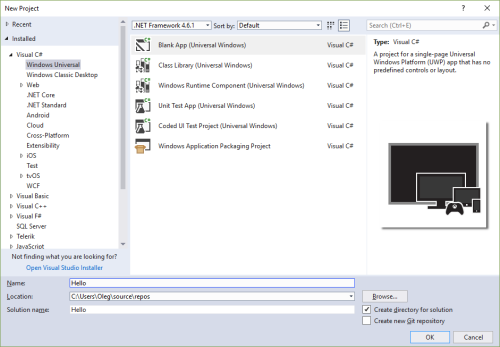

Software development in the bare metal model requires a development toolchain installed on the developer's computer. The vendor of the MCU usually provides a set of tools. This set frequently includes a dedicated compiler, linker, library management tools, configuration tools, debugger software, etc. These tools are command lines in most cases. Using a GCC [31] C/C++ compiler is also quite common. On top of it, a GUI with a rich UI interface is built to simplify software development. Some vendors provide their own GUIs, such as, e.g. STMicroelectronics' STM32CubeIDE (image 5), while others use already available universal code editing solutions and integrate with them, i.e. in the form of plugins or extensions.

Because documentation for the command line tools composing SDK is usually available, there are also universal solutions that enable developers to use a single GUI environment for various tasks and microcontrollers, switching among them quickly, such as Visual Studio Code (figure 6). Each platform requires its dedicated toolchain, anyway, and integration with universal code editors such as the aforementioned VS Code may be tricky. Luckily, there are tools to help with the automated installation of all required components, such as PlatformIO [33], that we describe below.

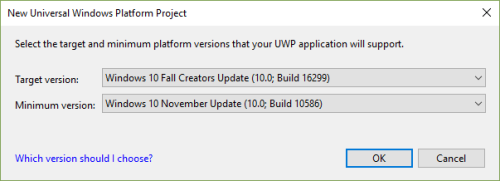

As the Arduino programming framework became a cross-platform standard, vendors provided low-level libraries implementing standard functionalities such as embedded communication protocols (Serial, SPI, I2C, 1Wire) and networking communication. Arduino, a manufacturer of popular development boards, provides an IDE (figure 7: Arduino IDE [34]) that is intended to be an entry-level development environment. It can be extended beyond genuine Arduino boards, i.e. with the Espressif toolchain for ESP8266 and ESP32. This software, however, is very limited in features and is suitable only for simple projects.

Developers Middleware and Support Tools

A number of additional tools usually come with the development toolchain provided by the hardware vendors. They include programmers (flashers, injecting firmware into the IoT device), configuration tools, power consumption calculators, etc. Installation is not always straightforward, and updating is tricky. Developers who use a variety of platforms (MCUs) struggle with instant updates, browsing the web for tools and sources. Moreover, handling libraries they use for development is time-consuming and involves instant monitoring of changes, manual copy-paste operations on files, etc. And it has to be done for every project individually.

PlatformIO

The solution is a developer's middleware that integrates with selected IDE and helps to install, configure and maintain toolchains for hardware, software development libraries, and also contains a set of additional tools (i.e. serial port monitor, JTAG debugger, code repository integration, collaboration tools, remote development, etc.). As mentioned above, one example of a handy middleware for IoT and embedded development is PlatformIO. It is a command-line toolset that provides a whole ecosystem for virtually any hardware platform; it still uses the vendor's proprietary toolchains. It perfectly integrates with Visual Studio Code (among others) via VS Code's extension (plugin) systems. VS Code works also as a GUI for PlatformIO. In the following figures, we present its look and UI when integrated with Visual Studio Code (figures 8, 9 and 10).

The solution is a developer's middleware that integrates with selected IDE and helps to install, configure and maintain toolchains for hardware, software development libraries, and also contains a set of additional tools (i.e. serial port monitor, JTAG debugger, code repository integration, collaboration tools, remote development, etc.). As mentioned above, one example of a handy middleware for IoT and embedded development is PlatformIO. It is a command-line toolset that provides a whole ecosystem for virtually any hardware platform; it still uses the vendor's proprietary toolchains. It perfectly integrates with Visual Studio Code (among others) via VS Code's extension (plugin) systems. VS Code works also as a GUI for PlatformIO. In the following figures, we present its look and UI when integrated with Visual Studio Code (figures 8, 9 and 10).

A PlatformIO-enabled IoT project is a set of files with a platformio.ini file in the root folder and main.cpp in the ./src/ subfolder (as, i.e. in the figure 8, project folder tree is to the left)). The platformio.ini file describes all technical parts of the project: the hardware platform, the method of uploading the firmware (usually via a serial port), software libraries that are included in the code and should be automatically pulled from the libraries repository during compilation and many other options [35]. Sample platformio.ini file is presented in the code below:

[env:d1_mini] platform = espressif8266 board = d1_mini framework = arduino upload_port = /dev/ttyUSB0 upload_speed = 9600 monitor_port = /dev/ttyUSB0 lib_deps = arduino-libraries/LiquidCrystal@^1.0.7 adafruit/Adafruit Unified Sensor@^1.1.7 adafruit/DHT sensor library@^1.4.4

This code configures the ESP8266 (Espressif) hardware project, with specific developer board D1 Mini and programming done in the “Arduino” framework development model.

Communication with the IoT device is via serial port (here /dev/ttyUSB0 for Linux or, i.e. COM3 for Windows) and uses the same port for monitoring (serial port monitor for tracing messages from the MCU and code).

It uses three libraries registered in the library registry for PlatformIO: LiquidCrystal, Adafruit Unified Sensor and DHT sensor library, with explicit versions. PlatformIO's Library Manager automatically checks for updates and proposes to update libraries to the latest available if a version is not explicitly stated. The Library Registry in the PlatformIO is a repository of the Gitlab project, available online [36]. Libraries are currently held per project instead of shared between projects.

At the start of the PlatformIO GUI and then periodically, it checks for PlatformIO updates and development toolchain updates, proposing to update them when a new version is available.

C/C++ Language Embedded Programming Fundamentals

The following sub-chapters cover programming fundamentals in C/C++, which comply with most C/C++ notations. Those who feel comfortable in programming will find these chapters somewhat introductory, while for those having no or little experience, it is highly recommended to cover this introduction. This chapter and its sub-chapters target the basics and general syntax of C/C++ programming for different platforms, including Arduino, Espressif, Nordic, STM32, and partially for Raspberry Pi devices; however, in any case, the programming environment configuration is different for every platform. The Arduino programming framework is common for many MCU manufacturers of the IoT Edge class devices in bare metal programming mode, even if bringing some overhead and does not let the developer push the devices to their limits. Thus we refer mostly to this one. To enjoy full power, efficiency and control of the specific device, one needs to use a dedicated SDK and Framework, but for teaching purposes and many even professional applications, Arduino Framework is suitable and a good balance between the cost of the development and the result.

Data Types and Variables

Almost every computer program manipulates the data. Data representation in the program is variable. In C/C++, the variable needs to be defined before using it, giving it some name and assigning chosen type, dependent on the kind of data. Here we show some common data types and how to use variables.

Data Types

Data type specifies how it is encoded and represented in the computer memory. For example, integer numbers are binary-encoded, the texts are represented as a series of ASCII-encoded characters, and real numbers have a particular encoding scheme that consists of two binary numbers - mantissa and exponent. Other data types are tables that consist of elements of the same type or structures with elements of different types. There are plenty of different data types, some of them are predefined, but user-own types can be defined based on existing ones. Creating a variable requires specifying its type, which determines its place in the memory of the microcontroller and also the way how it can be used. Further will be viewed the most used ones together with examples of defining variables.

- byte – a numeric type of 8 bits that stores numbers from 0 to 255.

byte exampleVariable;

The example above defines a variable, reserves its memory, and assigns the memory address to the variable name. It is also possible to give the variable the initial value as below:

byte exampleVariable = 123;

- int – the integer number. Its size depends on the microcontroller class. In the case of AVR (Arduino), it consists of 16 bits that can contain values from –32 767 to 32 768. In ARM-based microcontrollers (like STM32), its size is 32 bits.

int exampleVariable = 12300;

- float – a data type for real numbers that uses 32 bits and stores numbers approximately from –3.4 × 10^38 to 3.4 × 10^38.

float exampleVariable = 12300.546;

- array – a set of data of the same type that can be accessed using a serial number or index. The index of the first element is always 0. The values of an array can be initialized at the definition of it or set during the execution of the program. In the following example, the array of four elements with the name “first array” and data type int has been created. The value of the array with an index of 0 will be 12, and the value with an index of 3 will be 15.

int firstArray[] = {12,-3,8,15};

Square brackets of the array can be used to access some value in the array by index. In the following example, the element with index 1 (that is –3) is assigned to the secondVariable variable.

int secondVariable = firstArray[1];

An array can be quickly processed in the loop. The following example shows how to calculate the sum of all elements from the previously defined array (for statement will be explained in detail in the following chapters).

//The loop that repeats 4 times int sum = 0; for(int i = 0; i < 4; i = i + 1){ sum = sum + firstArray[i]; }

The loop in the example starts with index 0 (i = 0) and increases it by 1 while smaller than 4 (not including). That means the index value will be 3 in the last cycle because when the i equals 4, the inequality i < 4 is not true, and the loop stops working.

- bool – the variables of this data type can take values TRUE or FALSE. Arduino environment allows the following values to these variables: TRUE, FALSE, HIGH (logical 1 (+5 V)) and LOW (logical 0 (0 V)).

Data Type Conversion

Data type conversion can be done using multiple techniques – casting or data type conversion using specific functions.

- Casting – cast operator translates one data type into another type straight forward. The desired variable type should be written in the brackets before the variable data type, which needs to be changed. In the following example, where the variable type is changed from float to int, the value is not rounded but truncated. Casting can be done to any variable type.

int i; float f=4.7; i = (int) f; //Now it is 4

- Converting – byte(), char(), int(), long(), word(), float() functions are used to convert any type of variable to the specified data type.

int i = int(123.45); //The result will be 123

- Converting String to float – function toFLoat() converts String type of variable to the float. The following example shows the use of this function. If the value cannot be converted because the String doesn't start with a digit, the returned value will be 0.

String string = "123fkm"; float f = string.toFLoat(); //The result will be 123.00

- Converting String to Int – function toInt() converts String type of variable to the Int. In the following example, the use of this function is shown.

String string = "123fkm"; int i = string.toInt(); //The result will be 123

Defining New Types

Typedef Specifier

A typedef specifier can give another name for existing types or declares a new one. Renaming types is possible, but software development frameworks used have a number of aliases already. It is helpful, however, when combined with enumerations, classes and structures to give them reasonable names and re-use them later in the code to improve their readability. We present more details on structures in the chapter Structures and Classes, but here is an example presenting a reasonable use of the typedef specifier.

typedef struct {int x; int y;} tWaypoint; //Declare complex type named waypoint ... //Declare a variable of the type of tWaypoint tWaypoint wp1;

Enum Declaration

Enumerations are helpful to give meaning to the integer values and present some logic in a code instead of putting numbers into it. It can be, i.e., the device's state, error code, etc.

In the case a new enumeration is needed, it is possible to declare one using the enum keyword and specifying a list:

enum errorcodes {ER_OK, ER_DOWNLOAD, ER_UPLOAD, ER_NOWIFI}; //define enumeration ... errorcodes Errorcode; //declare a variable ... Errorcode = ER_DOWNLOAD; //assign a value

The default numbering starts with 0 (ER_OK=0) and increases by 1 with every next item on the enumeration list. However, explicitly defining values represented by the item labels is possible.

enum errorcodes {ER_OK=0, ER_DOWNLOAD=3, ER_UPLOAD=4, ER_NOWIFI=1};

Operators, Specifiers and Pointers

Operators represent mathematical, relational, bitwise, conditional, or logical data manipulations. There are many operators in the C/C++ language. In this chapter, the most important are presented. Logical operators will be shown in the next chapter as they are used together with conditional statements.

Assignment Operator

- Assignment operator ( = ) – the operator that assigns the value on the right to the variable on the assignment operator's left. The left side should represent the variable (must be able to be modified), and the right side can be the number (constant), variable, or expression. In the case of an expression, its value is first calculated, and then the result is assigned to the variable on the left. The work of an assignment operator can be seen in any of the following operation examples.

Arithmetic Operators

Arithmetic operations are used to do mathematical calculations with numbers or numerical variables. The arithmetic operators are the following.

- Addition ( + ) – one of the four primary arithmetic operations used to add numbers. The addition operator can add only numbers, numeric variables, or a mix of both. The following example shows the use of the addition operator.

int result = 1 + 2; //The result of the addition operation will be 3

- Subtraction ( - ) – the operation that subtracts one number from another where the result is the difference between these numbers.

int result = 3 - 2; //The result of the subtraction operation will be 1

- Multiplication ( * ) – the operation that multiplies numbers and gives the result.

int result = 2 * 3; //The result of the multiplication operation will be 6

- Division ( / ) – the operation that divides one number by another. If the result variable has the integer type, the result will always be the whole part of the division result without the fraction behind it. If the precise division is necessary, using the float type of variable for this purpose is important.

//The result of the division operation will be 3 //(Only the whole part of the division result) int result = 7 / 2; //The result of the division operation will be 3.5 float result2 = 7.0 / 2.0;

- Modulo ( % ) – the operation that finds the remainder of the division of two numbers.

//The result of the modulo operation will be 1, //Because if 7 is divided by 3, the remaining is 1 int result = 7 % 3;

Bitwise Operators

Bitwise operators perform operations on bits in the variable. Among them, there exist bitwise logic operations. It means the same logic function is applied to every pair of bits in two arguments. Bitwise or ( | ) means that if at least one bit is “1” at the chosen bit position, the resulting bit will also be “1”. Bitwise and ( & ) means that if at least one bit is “0”, the resulting bit is “0”. Bitwise operators shouldn't be confused with Logic Operators ( || ), ( && ), which operate on a single boolean logic value.

byte result = 5 | 8; ; //The operation in numbers gives the result of 13 ; //in bits can be shown as follows ; // 00000101b ; // 00001000b ; // --------- ; // 00001101b

byte result = 5 & 1; ; //The operation in numbers gives the result of 1 ; //in bits can be shown as follows ; // 00000101b ; // 00000001b ; // --------- ; // 00000001b

Bitwise operators also allow shifting data left ( « ) or right ( » ) chosen number of bit positions. Shifting is often used in embedded programming to access the bit at a specific position. Shifting data one bit left gives the result of multiplication by 2 while shifting one bit right gives the effect of dividing by 2.

byte result = 5 << 1; ; //The operation in numbers gives the result of 10 ; //in bits can be shown as follows ; // 00000101b ; // 00001010b

Compound Operators

Compound operators in C/C++ are a short way of writing down the arithmetic operations with variables. All of these operations are done on integer variables. These operands are often used in the loops when it is necessary to manipulate the same variable in each cycle iteration. The compound operators are the following.

- Increment ( ++ ) – increases the value of integer variable by one.

int a = 5; a++; //The operation a = a + 1; the result will be 6

- Decrement ( - - ) – decreases the value of the integer variable by one.

int a = 5; a--; //The operation a = a – 1; the result will be 4

- Compound addition ( += ) – adds the right operand to the left operand and assigns the result to the left operand.

int a = 5; a+=2; //The operation a = a + 2; the result will be 7

- Compound subtraction ( -= ) – subtracts the right operand from the left operand and assigns the result to the left operand.

int a = 5; a-=3; //The operation a = a – 3; the result will be 2

- Compound multiplication ( *= ) – multiplies the left operand by the right operand and assigns the result to the left operand.

int a = 5; a*=3; //The operation a = a × 3; the result will be 15

- Compound division ( /= ) – divides the left operand with the right operand and assigns the result to the left operand.

int a = 6; a/=3; //The operation a = a / 3; the result will be 2

- Compound modulo ( %= ) – takes modulus using two operands and assigns the result to the left operand.

int a = 5; //The result will be the remaining //Part of the operation a/2; it results in 1 a%=2;

- Compound bitwise OR ( |= ) – bitwise OR operator that assigns the value to the operand on the left.

int a = 5; a|=2; //The operation a=a|2; the result will be 7

- Compound bitwise AND ( &= ) – bitwise AND operator that assigns the value to the operand on the left.

int a = 6; a&=; //The operation a=a&2; the result will be 2

& and * Operators: Pointers and References

Simple and complex types can be referred to with the use of pointer variables. A pointer is a variable that holds the address of the variable. The length of the pointer is equivalent to the length of the memory address (usually 16, 32 or 64 bits). A pointer does not contain a value but rather points to the variable (a memory) where the value is stored. A pointer variable must be initialised and dereferenced with Address-Of and Dereferencing operators.

The following example presents a simple type declaration and the use of a pointer variable.

& operator returns an address of a variable.

* operator dereferences a variable (it provides access to a value that the pointer variable points to).

int n = 10; //Declare a variable of type int and initialize it with 10 int *ptr; //Declare a pointer variable. //At this point, *ptr does not contain any address yet, //rather some random address or null. ptr = &n; //Assign to the pointer ptr an address of the variable n //ptr contains now an address of the memory where variable n is located, //not a value 10 int k; //Declare another variable k = *ptr; //Assign k a value that is pointed by ptr